Lever Pull Espresso Machine

Overview

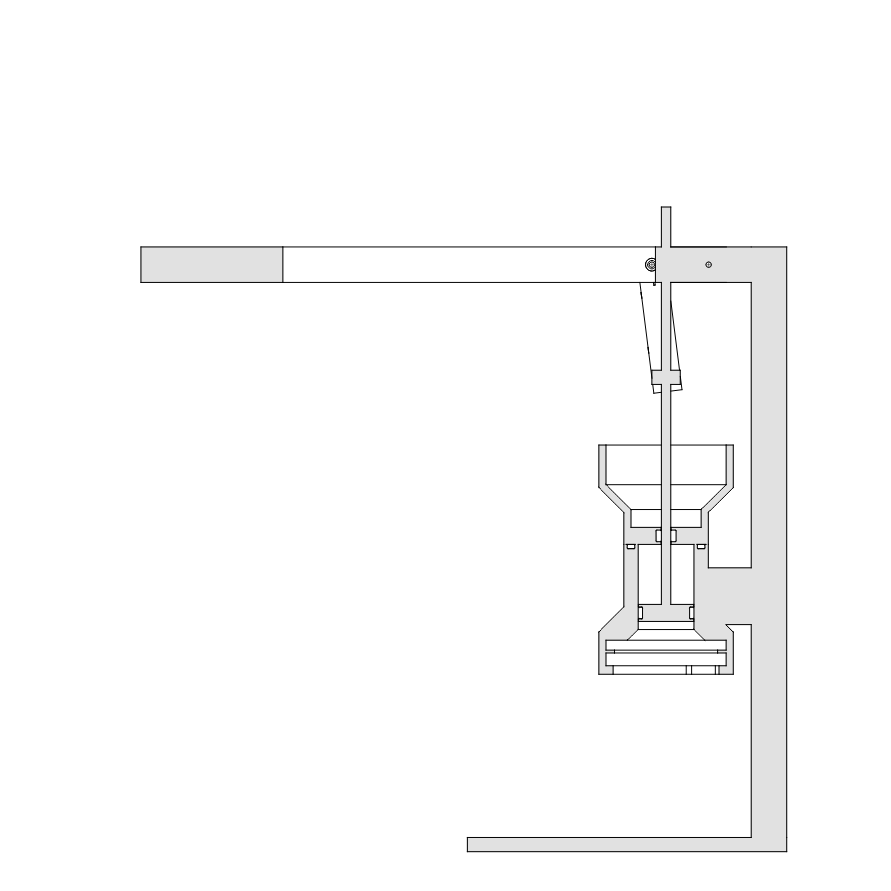

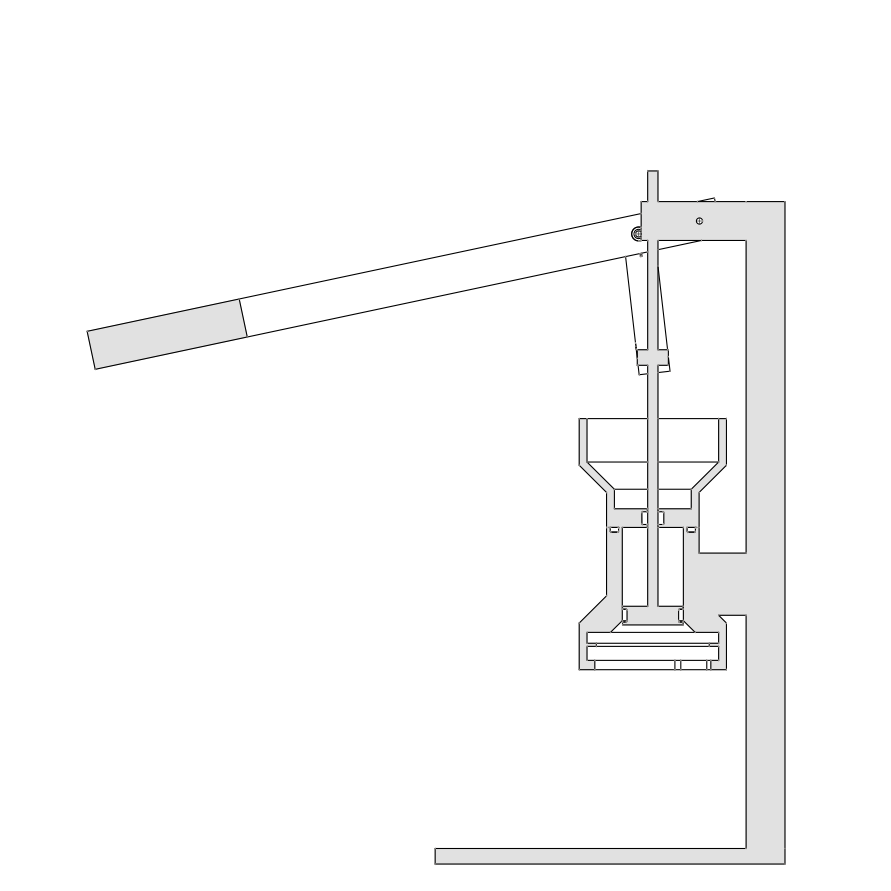

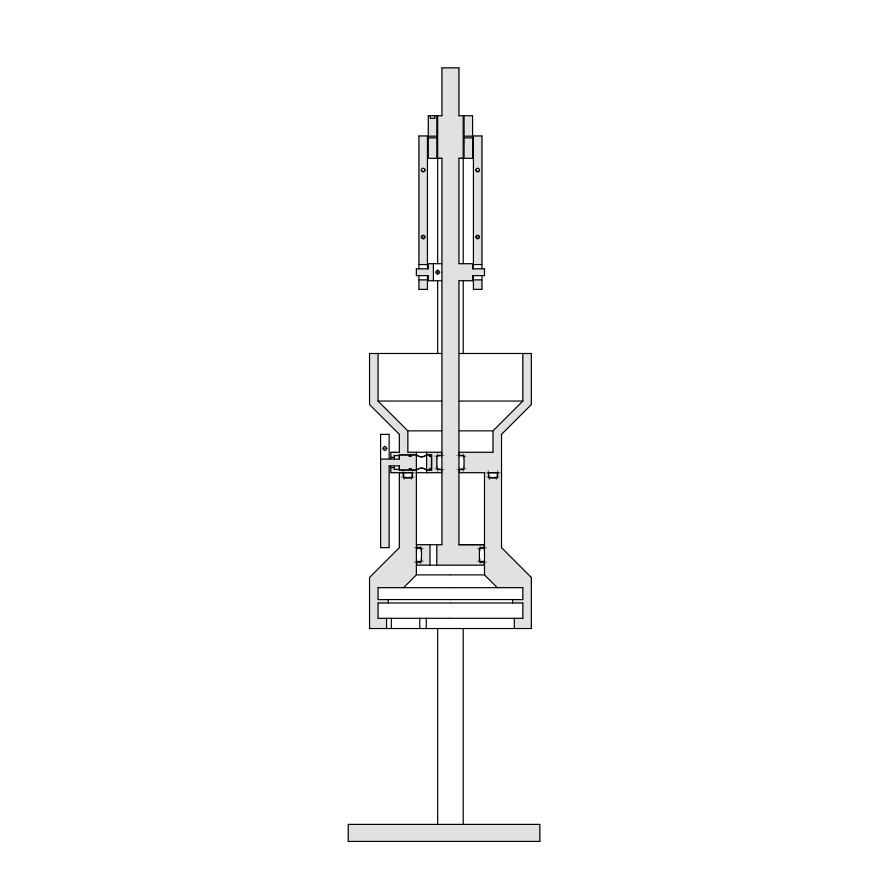

The espresso machine design shown here is operated by a lever arm that drives a piston through a connecting rod. Stresses, reactions, and kinematics were completed in Python file, which you can download by clicking here. Some of the figures used to determine part specifications are displayed in the gallery below as well. A factor of safety of 2 was used for stress calculations with the exception of the grouphead where a factor of safety of 4 was used.

Lever Movement

As the lever is pulled in a downward direction, it pushes the piston down along with it. The force applied to the end of the lever creates nine bar of pressure in the water that is under the piston, in a chamber called the grouphead. With the continued downward moment of the piston, water is forced through a basket of finely ground coffee (not shown), creating espresso.

Operation

Start by preheating the body my running water at 100 °C through the espresso machine, this is to minimize thermal loss to the body while puling an espresso shot in the following steps.

With the lever in the upmost position and the plug valve closed, add 100 °C water to the well.

Open the valve and push the lever down to suck water in to the upper grouphead chamber. Minimize the addition of air into the upper chamber.

Close the plug valve.

Insert the Portafilter (not shown here) with tamped coffee into the bottom of the grouphead.

Move the lever into the upper position. This forces water through the check valve in the piston head and into the lower grouphead chamber.

Pull the lever down to push the water through the coffee in the Portafilter.

Clean coffee grounds from Portafilter and grouphead.

Lever in Highest Position

Lever at 120deg

Lever at 90deg

Lever At Lowest Position

Front Section View

Assembly

Base

The other three bodies are supported by the base, which is itself composers of thread bodies. A flat plate, a vertical pillar, and a horizontal cantilevered beam. The flat plate supports the vertical pillar, which in turn supports the grouphead and cantilevered beam.

Lever Mechanism

The lever mechanism is what creates pressure in the grouphead and in doing so creates espresso. It is composed primarily of two lever arms attached by a handle, tow connection rods, the piston rod, the piston head. Other components include bearing, bolts, washers, pins, seals, and a check valve.

The downward motion of the lever, whose fulcrum is pin connected to the base’s cantilevered beam, drives the connection rod down along with it. The piston and lever are connected by the connection rod, so as the lever moves down it pushes the piston down through the grouphead chamber. The piston head had a check valve to allow water to pass through it when the lever is being pulled up, this allows for the group head to be filled with water.

Grouphead

The grouphead, which is bolted to the body’s vertical pillar, is a cylindrical pressure vessel. As previously stated, the pressure is created by the piston, which is functionality the top head of the pressure vessel. The bottom of the pressure vessel is closed when a portafilter (not shown) containing coffee attached.

Well

Above the grouphead is mounted the well. This where water is added to the espresso machine. The well body consists of a cylinder opened at the top, a plug valve, and a seal. When the plug valve is opened water is allowed to move from the well into the grouphead above the piston.

Base

Lever Arm

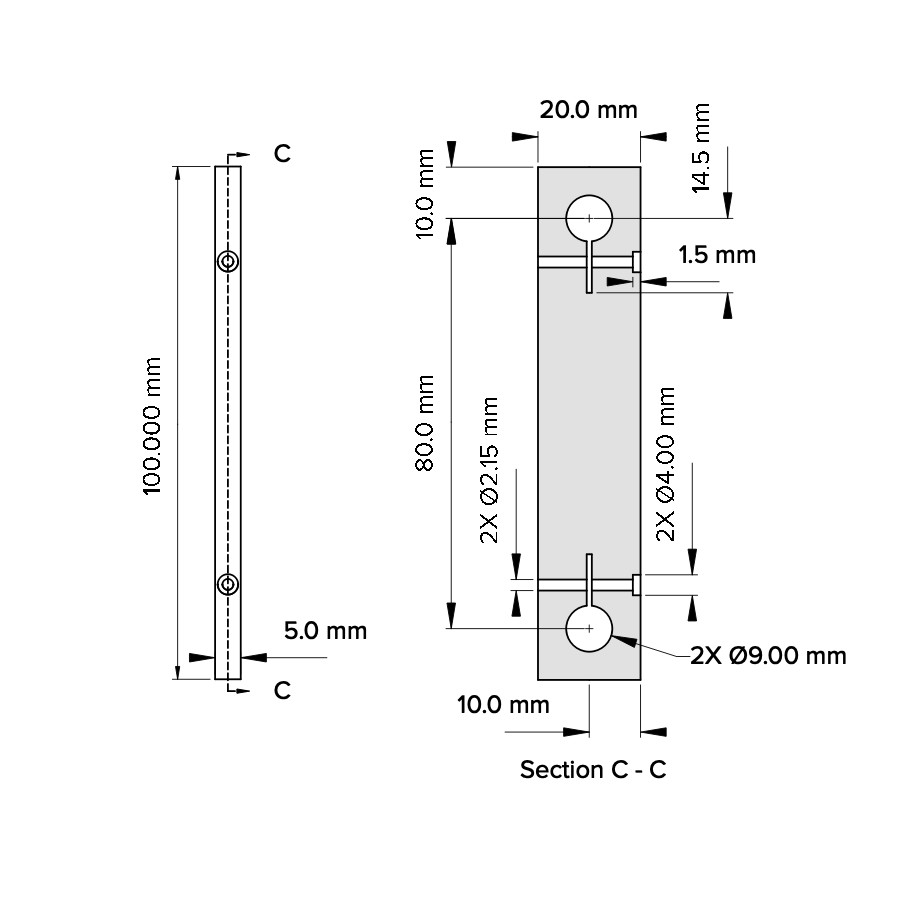

Connection Rod

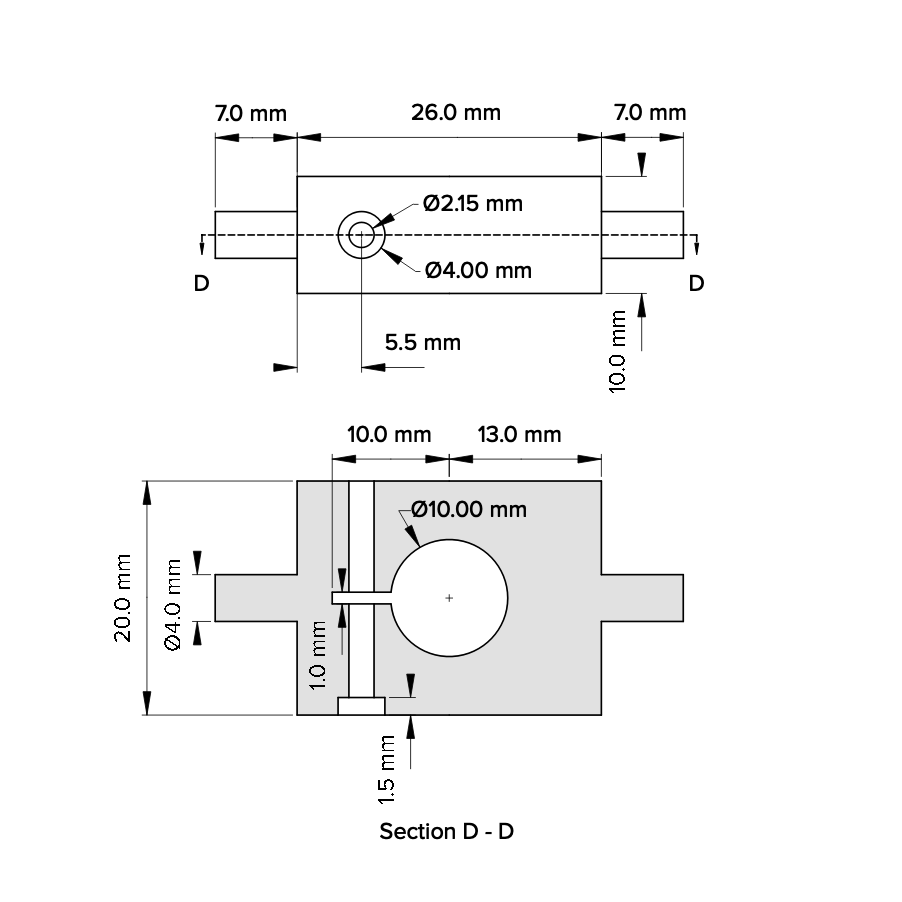

Rod Link

Piston Head & Piston Rod

Grouphead

Well

Plug Valve & Valve Lever

Plug Valve Cover Plate

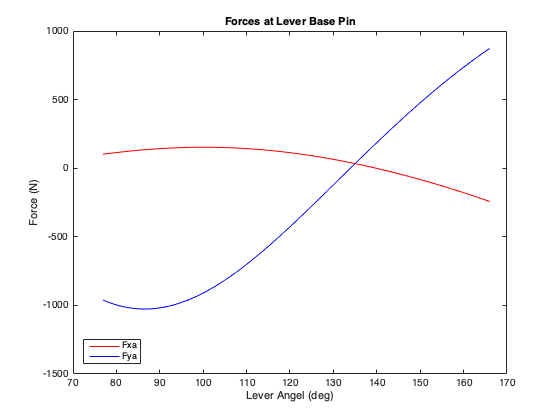

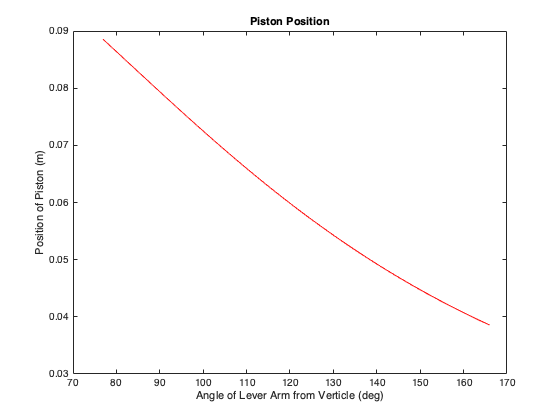

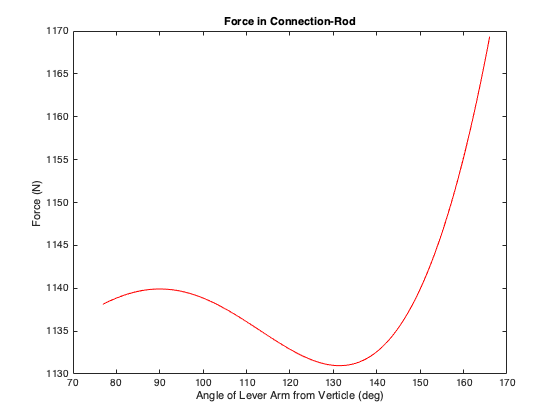

Figures & File

Shown here are the figures compiled from the Python calculations. These were used to determine the required sizing of components with the known maximum allowable normal and shear stresses along with the chosen factor of safety. Additionally shown are the internal max shear forces and moments in various components.